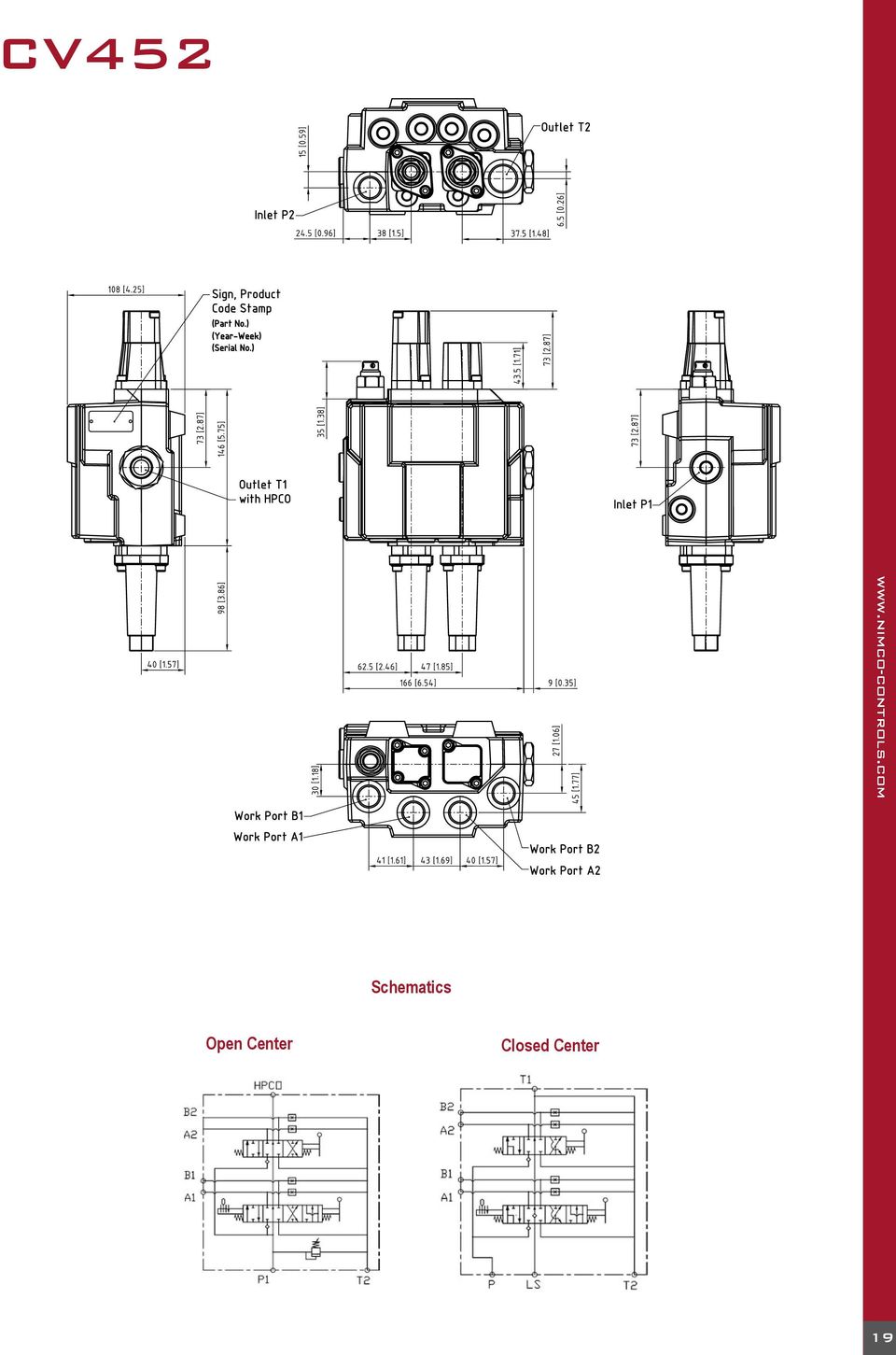

Sourcing a good replacement can be tough. Might be easer to repair the one you have. Just with a quick look, that valve is a 6 section valve, one float spool and 5 double acting. It has load checks on both A and B side of each spool. It is rated @ 24 GPM and has a internal leakage of about 3 cc per minute. It has 2 anti cavitation valves.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features Press Copyright Contact us Creators. Nemco Parts & Manuals Parts Town has the most in-stock Nemco parts on the planet for your commercial kitchen. Choose from a wide variety of elements, slicer blades, O-rings and more to repair and maintain your equipment. Nimco Controls is synonymous with low leakage Directional Control Valves. One of the key performance factors in any machine is how well the load is controlled. The machine operators can perform more work in a safer way if they are operating a machine with a well designed Directional Control Valve.

Directional Control Valves

Nimco offers Load Sensing Flow Sharing Valves with Electrical Proportional Control Units and Software

Optimal Solutions For The Mobile Industry

Nimco offers a broad range of Open Center Valves suitable for all mobile machine applications

Hydrostatic Steering & Orbital Motors

Nimco's low speed, high torque motor options are perfect for vehicles or applications requiring robust, highly efficient reliability in heavy duty applications

Nimco Control Valve Repair Manual Free

Remote Control Units

Nimco's integrated electro-hydraulic systems will optimize machine performance with increased output productivity and enhanced load control and safety

Nimco Control Valve Repair Manual Parts Diagram

1 ) Typically, most control valves found on cars today are not the original units withthe original components. Many valves have been swapped off of different yearand car models from junkyard cars and such. Often some of the pieces have beenchanged out somewhere along the line. The valve may have been previously exchangedwith a rebuilt unit which in itself may have been pieced together from severaldifferent units. While most Bendix valves use many of the same parts throughoutits production, many pieces are different and uniquely designed for certainapplications. Granada parts are a popular swap item these days, but many Granadacontrol valves (though identical in exterior appearance) are quite differentfrom other valves by not having any reaction valve components at all. Even somenew reproduction control valves contain parts that are of poor quality anddesign and should be changed out during a rebuild. Be aware that the valve on your car may not be correct for the application it isbeing used on and some parts may need to be changed in order for the valve to operateproperly. 2 ) You cannot always rely on the plan to reassemble the valve based on the way it wasassembled when you took it down. Many valves have already been improperly assembledby a previous owner or mechanic, even sometimes professional rebuilders.Depending on the brand and distributor of the rebuild kit you buy, the includedinstructions (if any) are likely to be fair to worthless. Many kits are soldwith a generic instruction sheet that has been through so many generations of photocopiesas to be practically illegible. Even the instructions and illustrationsfound in factory Ford shop manuals have mistakes and inaccurate information.Sometimes the information given will not even work on the year and model valvethe book claims to cover. The most important thing to remember is that typical kit and shop manual instructionswere originally designed for mechanics that worked on these valves duringa warranty period or reasonable time span from when the car was new. They do notaddress the problems and situations that can come up on rebuilding a 25-40 yearold valve that may or may not be complete, original or in rebuildable shape. 3 ) There are several problems that often damage a control valve due to physicalenviroment and mechanical action. One such problem is rust corrosion due towater getting inside the hydraulic system itself or inside non-pressurized areasof the valve. It may not seem likely, but water inside the fluid system is acommon problem. Water tends to get in no matter what, and in the power steeringsystem, tends to settle in the lower components, such as the control valve. Thiscan cause the valves inside to rust and pit, which can cause seals to fail,pieces to stick and parts to freeze up completely. More commonly, water gets inareas not a apart of the pressurized areas and affect parts not even benefittingfrom the washing action of the fluid system. Keep in mind that the control valvesets under the car and catches a lot of water thrown up from the road. Duringcertain turning conditions, the drivers side tire literally drenches the valvewith water and spray while driving. Examples of these problem areas are illustratedbelow. 4 ) The steering linkage is also subject to physical abuse in many areas. Most of thisis caused by bottoming the valve or linkage on something, but some years mayhave damage simply because the wheel alignment was improperly done. A lot of physicaldamage is done by owners and even professional mechanics during removaland aseembly of the parts on the car. Proper use of the proper tools is important to avoid this damage. Never use a 'pickle fork' to separate steering linkage. This tool alone is responsible for most of the physical damage we see each day.Using it will damage parts and may make them unusable. |

Comments are closed.